Features

Ultrasonic Flow Sensor Benefits

No straight-pipe requirement! Place immediately after a bend or valve, even in the same valve box

(Jumbo size valve box recommended for easiest fit)

Read very low and high flow, all in one sensor

No moving parts for greater reliability and allowing blowout for winterization with the sensor installed

Pressure rated to 200 PSI and an operating temperature of 32 - 150 degrees Fahrenheit

On-board LED Lights indicating power, full pipe status, relative forward flow rate, and reverse flow

Simple setup at the controller with a standard K and Offset value for wide compatibility

Flow Sensors Enable Key LX Series Controller Features

Flo-Watch™. Flo-Watch constantly monitors for low flow and excess flow conditions caused by broken lines or heads, automatically quarantines and shuts down the problem area, and continues to irrigate non-affected areas. Saves water, saves plant material, and enables irrigation programs to continue and complete

Learned Flow. The controller automatically learns station flow rates resulting in more accurate flow rates. The automatic collection prevents you from having to manually enter data from drawings, or physically visiting each valve to collect flow data and manually entering the data into a controller

FloManager®. FloManager determines the optimal station irrigating sequence. The system runs at its fullest capacity until programs are complete. The controller automatically selects and runs multiple valves at the same time within hydraulic parameters, allowing for shorter water windows

Using With Transmitters and Pulse Decoders

Programmable from a computer (PT322 and PT5002 – Maxicom and SiteControl Systems only – not required for ESP-LXMEF or ESP-LXD)

Reliable solid-state design, available with or without LCD display (PT322 only)

Operates with MAXILink,™ and (hard-wire) two-wire satellite systems

Easy-to-program, menu-driven design

Mounted in optional NEMA enclosure (PT5002 only)

Specifications

Flow Range

UFS100: 0.3 - 50GPM

UFS150: 0.5 - 110GPM

UFS200: 1.0 - 200GPM

Sensor Attributes

Accuracy: +- 2% (non-variable, across full flow range)

Velocity: 2-20 Feet (0.6-6.1 meters) per second depending on model and system specifications

Pressure: 200 PSI Working Pressure

Temperature: 32° - 150° F (0° - °65 C)Working Temperature

Configuration

For ESP-LXIVM 2-Wire Systems: the Flow Sensor is installed with a 2-Wire Sensor Device (LXIVMSEN)

For ESP-LXD Decoder Systems: the Flow Sensor is installed with a Two-Wire Decoder Sensor Decoder (SD211TURF) (Previously SD210TURF)

For ESP-LXMEF Systems: the Flow Sensor is attached to the FSM-LXME Flow Smart Module

For ESP-LXME2 PRO Systems: the Flow Sensor is attached to the Pro Smart Module Flow +/- terminals

For (Hard Wire) Two-Wire Satellite Systems (Maxicom²® and SiteControl): the Flow Sensor is installed with a Pulse Transmitter and a Rain Bird Pulse Decoder (DECPULLR)

For Link Radio Satellite Systems (Maxicom² and SiteControl): the Flow Sensor is installed with a Pulse Transmitter (no pulse decoder required)

For ESP-SITE Satellite Systems (Maxicom): the Flow Sensor is installed with a Pulse Transmitter (no decoder required)

For SiteControl Decoder Systems: the Flow Sensor is installed with a Two-Wire Decoder Sensor Decoder (SD211TURF) (Previously SD210TURF)

*Surge protection (FSSURGEKIT) is recommended for Maxicom and SiteControl systems – One at the Pulse Transmitter, and if more than 50’ of wire run, one at the Flow Sensor. FSSURGEKIT is not compatible with ESP-LXMEF and ESP-LXD Controllers

Dimensions

UFS200 - 10 1/2” x 4 3/4” H = 3 7/8” (267mm x 121mm x 98mm)

UFS150 - 101/2” x 4 3/4” H = 4 3/8” (267mm x 121mm x 111mm)

UFS100 - 101/2” x 4 3/4” H = 4 7/8” (267mm x 121mm x 124mm)

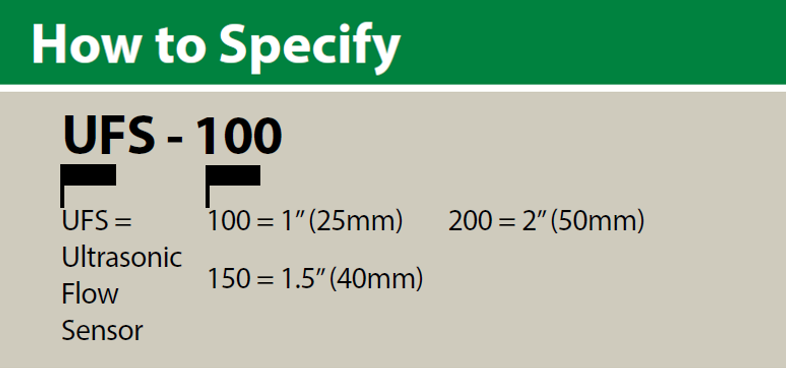

How to Specify