Features

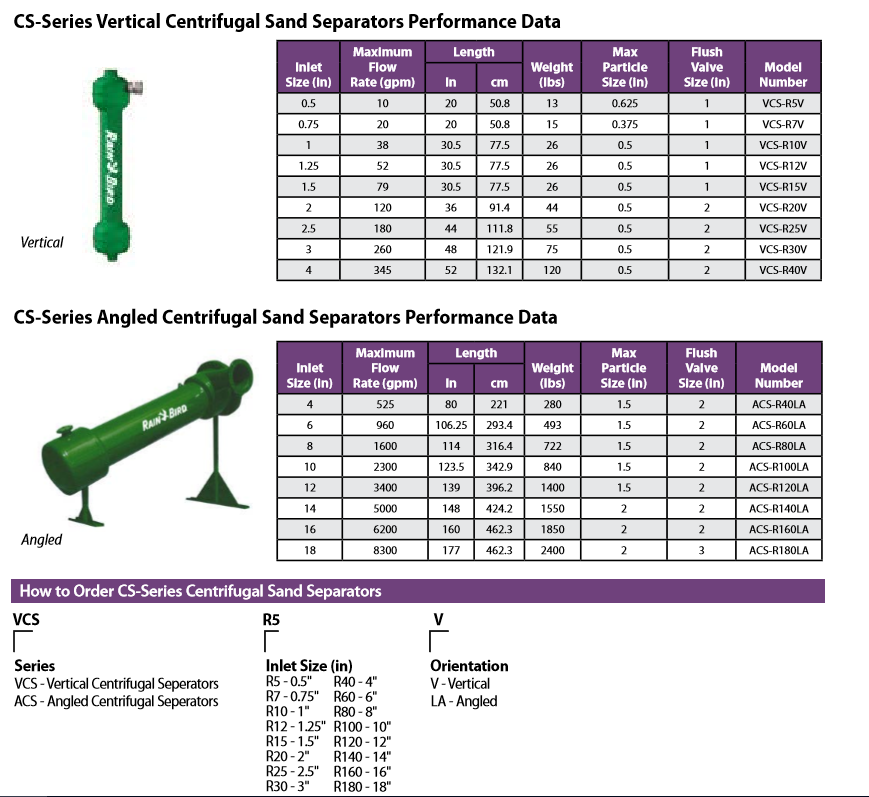

Capacities of 4 to 8300 gpm

Simple installation (no electrical power required)

Efficient pre-filter to reduce sand load on downstream components

Rain Bird Centrifugal Sand Separators are designed to separate abrasive particles before they can enter the irrigation system, keeping equipment clean and clear of debris, which minimizes the amount of maintenance required and increases operational efficiency

The separator removes sand and particles that are heavier than water (materials with a specific gravity of 2 or greater)

How It Works

Liquids and solids enter the unit and begin traveling in a circular flow. This centrifugal action throws heavier particulates towards the filter walls and eventually downward in a spiral motion to the separation chamber. The particulates collect in the separation chamber and are purged manually from the system. The filtered water is then drawn to the separator’s vortex and through the outlet

An optional automatic purge controller and valve can be used on all applications to automate the purge process, which eliminates the need for manual flushing. Small vertical design separators may be wall mounted or supported by the system piping

Specifications