ESP-LXD Series 2-Wire Decoder Controllers

50 – 200 station capable 2-Wire Decoder Commercial Controller

The ESP-LXD controller has been designed to maintain the look, feel and ease of programming of the ESP-LXME controller but with an interface to a 2-wire path for decoder-based irrigation. The ESP-LXD controller can manage up to 50 stations but can easily be expanded for use with up to 200 stations. Flow Management is also built into every ESP-LXD controller.

Compatible with IQ4: Allowing users to control/ monitor 1 to 1000s of controllers from their computer or mobile device

Use this controller with IQ4 Central Control

Videos

Features

Controller Features

50-station capability standard expandable to 200 stations with optional ESPLXD-SM75 modules

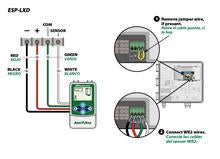

Four available sensor inputs (one wired plus up to three decoder managed) with override switch

Five flow sensors supported

Supports SD-211TURF sensor decoders (flow sensing and weather sensor support) and LSP-1 line surge protectors (one per 500 feet of 2-wire path required)

Central Control capable with Rain Bird IQ Communications Cartridges and software (see pg. 102)

Advanced Features From Cycle+Soak™ to Contractor Default Program™, the ESP-LXD offers innovative features proven to cut installation expenses, troubleshooting time and water use

Program backup and barcode decoder address entry with the optional PBCLXD

Six user-selectable languages

Removable front panel is programmable under battery power

Plastic, locking, UV resistant, wall-mount case, Optional Metal and Stainless Steel Case & Pedestal

Compatible with Rain Bird Landscape Irrigation and Maintenance Remote - Flow Smart Module™ factory installed or field upgradable

Specs

Operating Specifications

Station timing: 0 min to 12 hrs

Program level and global Monthly Seasonal Adjust: 0% to 300% (16 hrs maximum station run time)

4 independent programs (ABCD): ABC programs stack, ABCD overlap

Supported decoders: FD-101TURF, FD-102TURF, FD-202TURF, FD-401TURF, FD-601TURF

8 start times per program

Program Day Cycles include Custom days of the week, Odd, Odd no 31st, Even, and Cyclical dates

Manual station, program, test program

Certifications

cULus [US and Canada], WaterSense (when upgraded with ET Manager Cartridge) [US], CE [European Union], IPX4, RCM [Australia and New Zealand], Smart Approved WaterMark [Australia]

Electrical Specifications

Power Supply Voltage: 120 VAC ± 10%, 60Hz (International models: 230 VAC ± 10%, 50Hz; Australian Models: 240 VAC ± 10%, 50Hz)

Power back-up: Lithium coin-cell battery maintains time and date while nonvolatile memory maintains the schedule

Multi-valve station capacity: up to 2 solenoid valves per station; simultaneous operation of up to eight solenoids and/or master valves

Multi-valve station capacity: up to 2 solenoid valves per station; simultaneous operation of up to eight solenoids and/or master valves

Dimensions (W x H x D)

14.32” x 12.69” x 5.50” (36.4 x 32.2 x 14.0 cm)