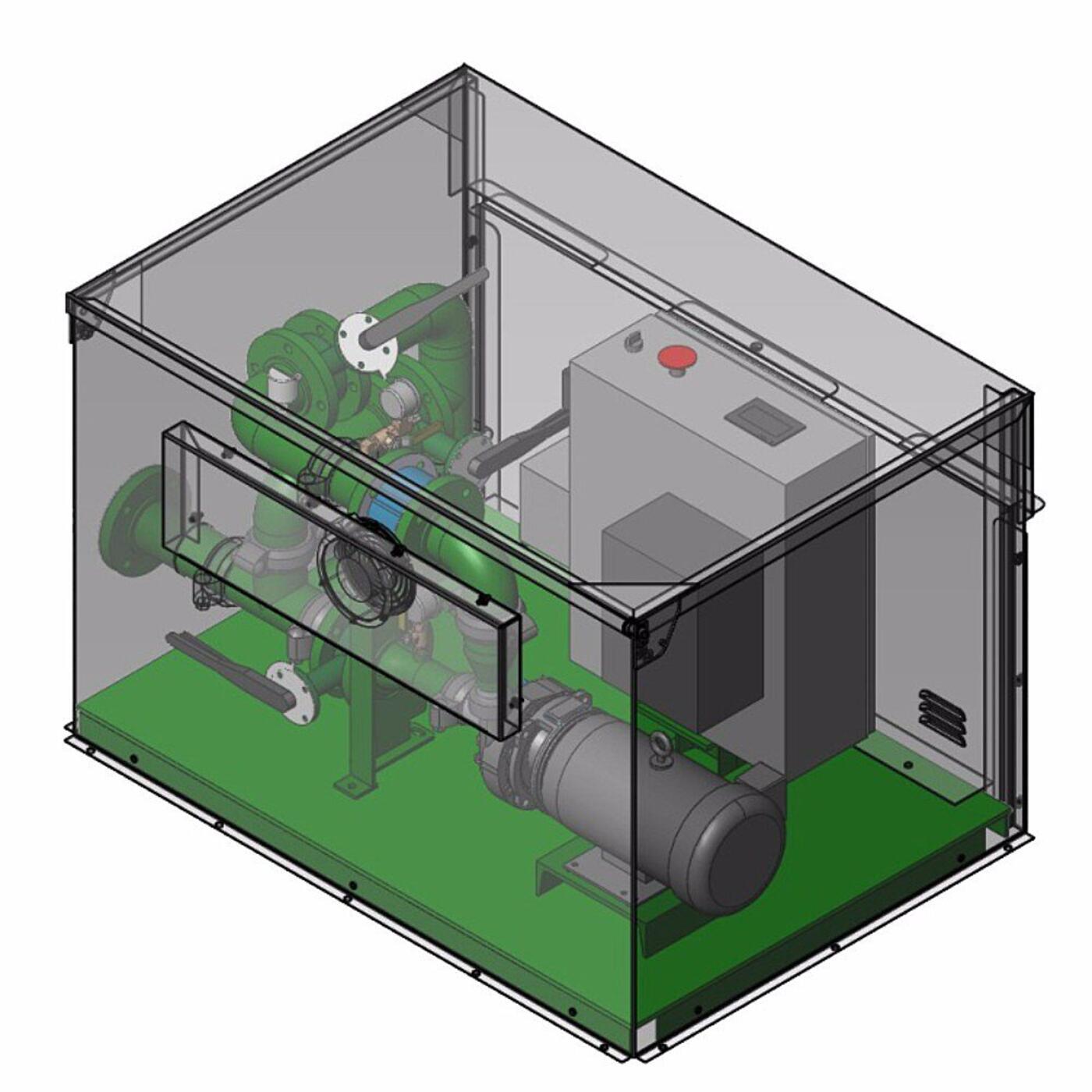

Pump Stations and Filters

System-Powering Performance and Efficiency.

Rain Bird applies our world-leading irrigation expertise to the design and manufacture of golf pump stations and filters. As part of a fully integrated Rain Bird irrigation system, these pump stations bring real-time response to your pump, monitoring the operation of the pump and maximizing flow throughout the irrigation cycle. You’ll get reduced water use, lower energy costs and less wear and tear on your pump station.

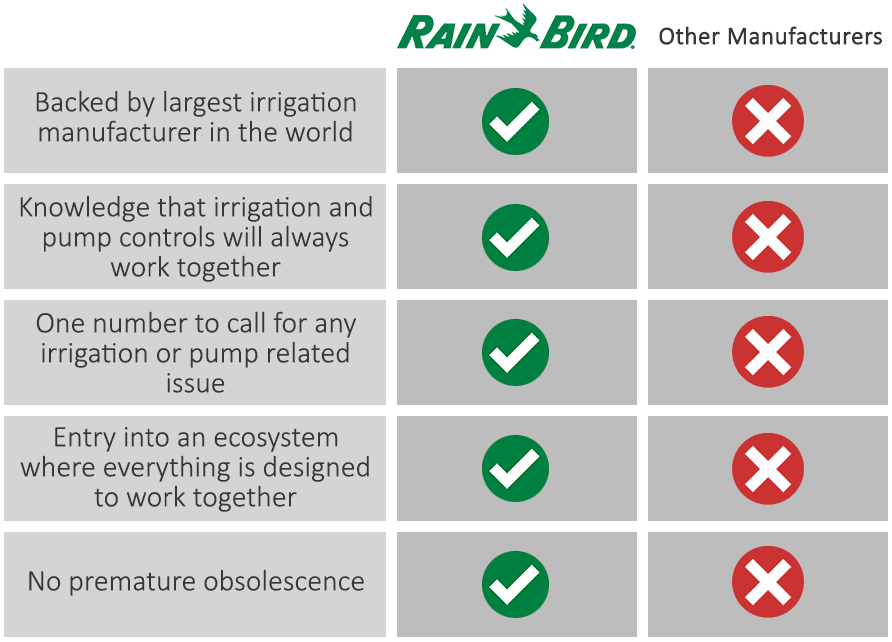

The Rain Bird Difference