MAXIMIZE ENERGY SAVINGS

With VFD Booster Pumps

MAXIMIZE ENERGY SAVINGS

With VFD Booster Pumps

The Importance of Pressure

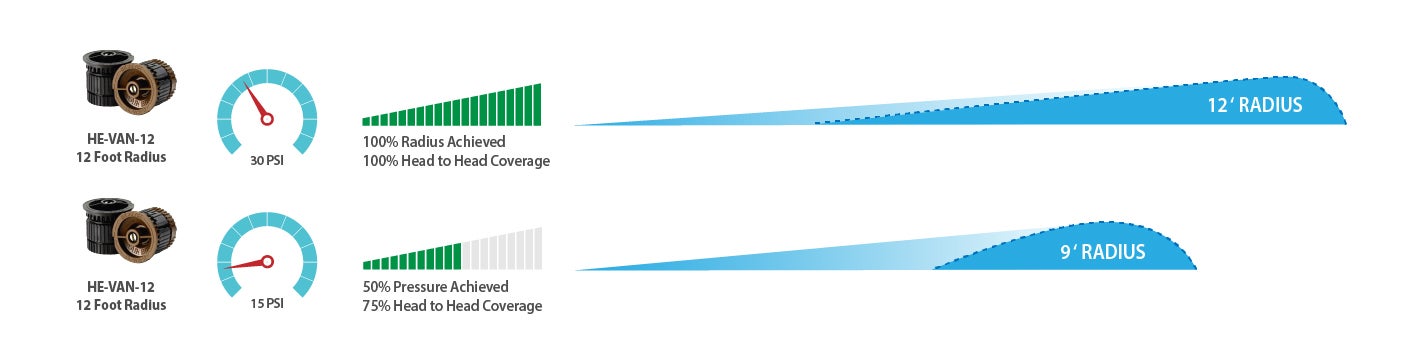

Correct pressure is vital to total system performance—and ultimately—water conservation. We often talk about excess pressure and associated water waste, but what happens when you don’t have enough pressure?

SIGNS OF INADEQUATE PRESSURE

Sustainability Suffers Under Inadequate Pressure

As a consequence of inadequate pressure, there is an inconsistent distribution of water throughout the system. This causes some areas to get wet while others remain dry. Oftentimes, the end user will run the system longer to reach the dry areas while simultaneously over-saturating the wet areas. Ultimately, low pressure uses more water than necessary to keep plants from wilting or dying.

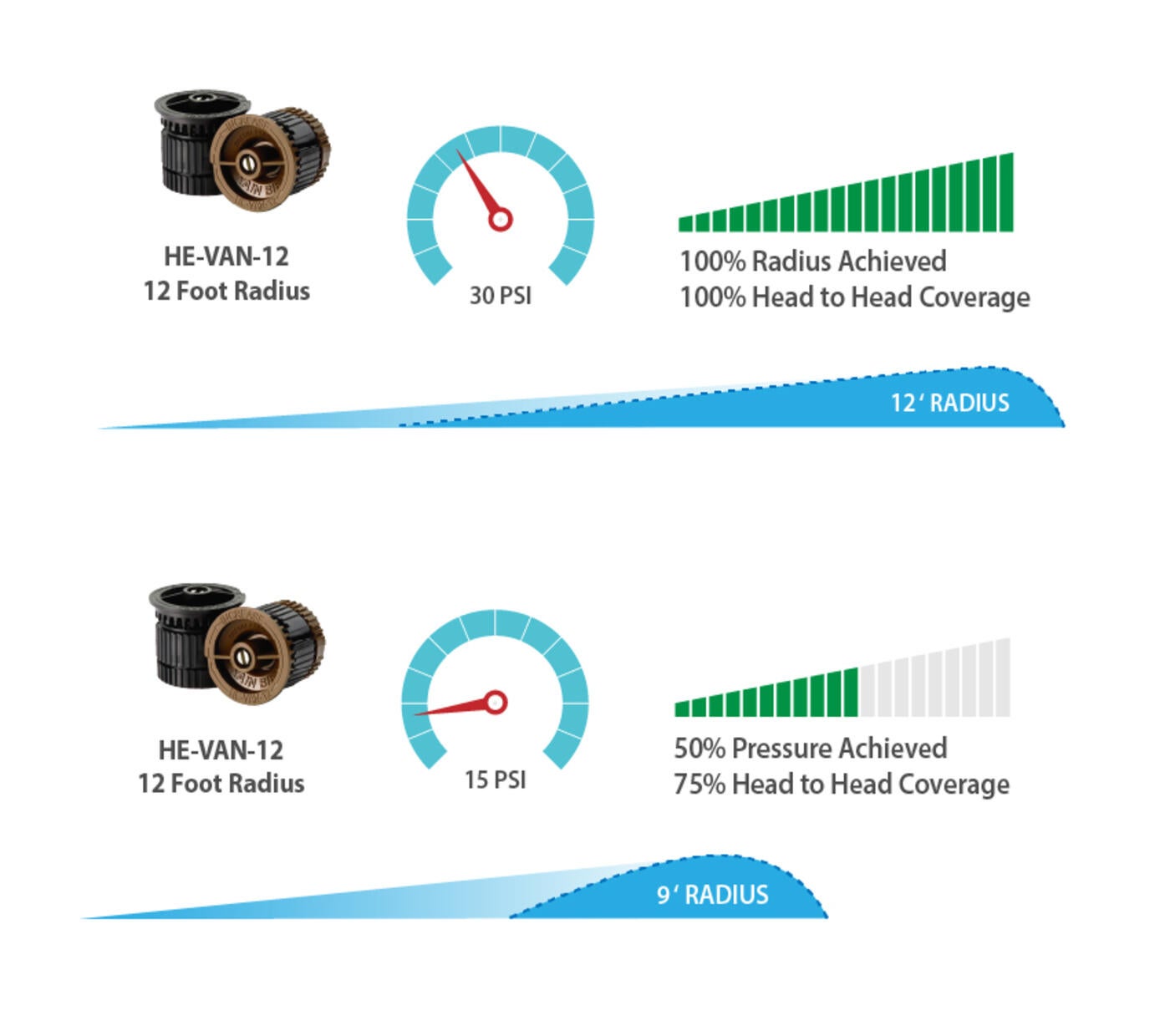

Product Pressure Requirements:

Depending on the valve's distance and elevation from the POC, as well as the type and number of devices it is servicing, dynamic pressure requirements can vary greatly. Below are the different types of emission devices and their required pressure for optimal distribution uniformity.

EXAMPLE:

If you are running a 60 HP pump capable of 600 GPM at full capacity for a station that only needs 400 GPM or 40 HP, then you are wasting about 20 HP for the duration of that station's runtime. The VFD allows you to reduce the horsepower required to match the need. In this scenario, you would expect to see a 30% power reduction by using a VFD to decrease the max capacity from 60HP to 40HP.