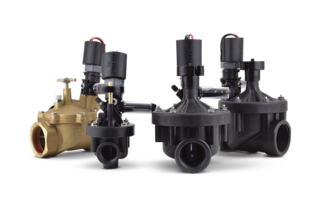

IC Rotors & Valves

A Revolutionary Approach to Field Control.

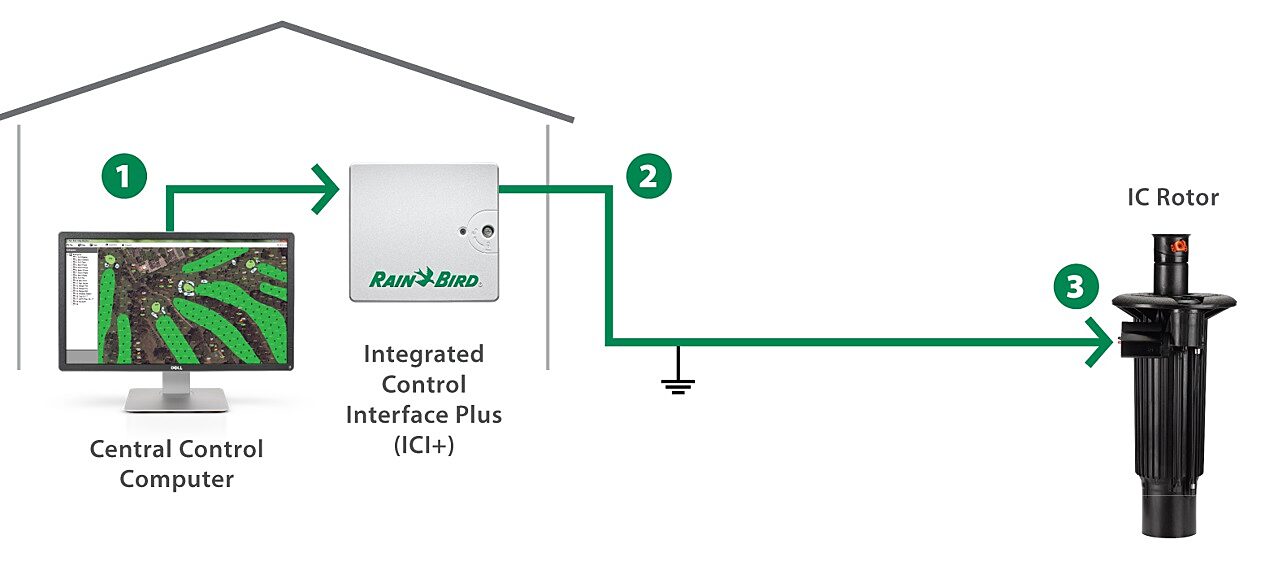

The Rain Bird® IC System™ connects central control directly to every rotor and valve, providing exceptional course conditions, with unmatched water and energy efficiency. No field controllers, separate decoders, secondary wiring, or unnecessary splices means simplified design, reliable operation, and easy expandability.

The Revolutionary Diagnostics of the IC System allows the golf course to monitor status and proactively resolve issues from anywhere, anytime, providing true peace of mind. This exclusive innovation prevents turf damage and saves time.

Videos

Features

Streamlined Installation and Expansion

Cut installation cost and time by eliminating unneeded wire, trenching, and splices.

Minimize labor costs during expansion by simply connecting new IC rotors to any existing Maxi Wire.

The Integrated Control Module (ICM) offers tear-off bar codes and an easy-to-use scanner to simplify the creation of the central control system database for quick operation. As soon as the wire path is connected to the computer, you can turn on the sprinklers and valves.

The IC System is easier to design — only simple calculations are required. It eliminates an array of troublesome considerations—there are no satellite controllers to design around or conceal.

Pinpoint Diagnostics and Control

Check the status of up to 1,500 individual rotors in 90 seconds or less.

Narrow in on problems and resolve issues quickly to prevent turf damage and unnecessary labor costs.

Bring greater precision and water savings to areas requiring supplemental watering (hot spots, greens, grow‑ins).

Simplified Design

By eliminating up to 90% of the wire and all decoders and satellites, IC System protects the aesthetics of your course while streamlining installation, maintenance, and expansion.

Since the ICM is built right into the rotor or valve, the entire control system is below ground. Unlike field controller systems, the below-ground system offers protection against damage from vandalism, flooding, and insects.

Since the IC System control is designed to be entirely below ground, the golf course vistas are clear of irrigation components as envisioned by the golf course designer. The IC System allows the full benefits of Rain Bird central control systems including ET-based scheduling, customized course graphics, multiple mapping options, and the ability to “see” the placement and operation of individual rotors.

Reliable Control

The IC System is a simple yet sophisticated controller/rotor/valve system built around a new generation of Rain Bird’s proven solenoid and satellite technology. Simplicity results in reliability.

The IC System is designed to always turn off if problems occur. When the wire path is damaged or cut, or if central control communication is lost, the ICM is designed to turn off automatically.

True “Below 30 Volt Control System”

As the IC System wire path output is 28 Volts, the IC System is a “true less than 30 Volt control system.” A lower than 30 Volt system is considered a low voltage system and is typically not subjected to code requirements regarding deep burial of the wire path.

Specs

System Capacity*

750 ICMs per Output Wire Path, 1500 ICMs per Output Driver Board, 3000 ICMs per IC Interface (ICI), up to 36,000 ICMs with Cirrus.

* Specific System Capacity is dependent on the Central Control System ICI

Electrical Input

100 VAC Nominal 91-110 VAC @ 60 HZ +/- 2 HZ,115 VAC Nominal 98-132 VAC, 220-240 VAC Nominal 208-255 VAC

Electrical Output

26.5 VAC, 1.25 AMP Per Wire Path

Active Stations

No electrical limit — only limited by hydraulics of pipe network and size of pump station.

ICM Current Requirements

Varies based on wire path length — Nominal Current Draw is 0.33 mA on 5000 feet (1500 meters) of wire.

Grounding Requirements

ICSD to be grounded at less than 50 Ohms every 500 feet (150 meters) or 15 ICMs whichever is less. The Central Control is to be grounded with less than 10Ohms of resistance.

Compliance

CE, FCC

Environment

Working Range: 32° F to 122° F (0° C to 50° C)

Storage Temperature: -40° F to 150° F (-40° C to 65° C)

Operating and Storage Humidity: 100%

Dimensions

IC Module: 2.23" x 1.70" (57 mm x 43 mm)

ICSurge Device: 2.00" x 1.41" (51 mm x 43 mm)

Maximum Wire Paths

2 Outputs per IC Driver Board and Up to 4 total per ICI and Multiple Branches per Wire Path.